Servo motors are integral to modern automated systems and precision-dependent machinery. These components are pivotal in various applications, ranging from industrial manufacturing equipment to sophisticated robotics. They are prized for their ability to precisely control the speed, position, and torque of a system, making them essential for ensuring high-performance output. This article explores the relationship between the maintenance of servo motors and the overall efficiency and productivity of the machines they control.

The Role of Servo Motors in Machine Systems

Functionality and Integration

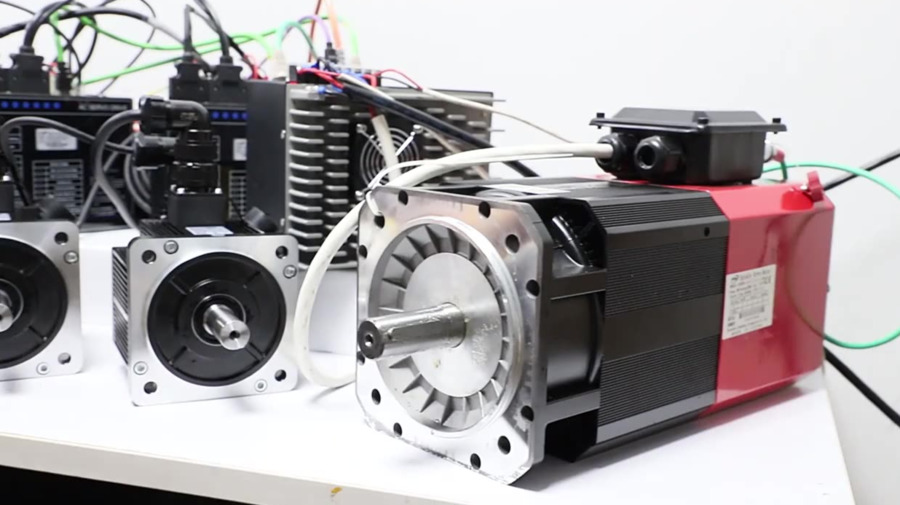

Servo motors are versatile components used in numerous machine types. In manufacturing lines, they adjust operational speeds and movement precision, ensuring products are assembled with meticulous accuracy. In robotics, they facilitate complex movements and tasks, allowing robots to perform with high agility and exactitude. The integration of servo motors thus directly affects the core operations of these systems, determining their efficiency and effectiveness in performing designated tasks.

Efficiency Metrics for Servo Motors

The efficiency of servo motors is often evaluated based on specific performance indicators such as speed, accuracy, torque, and responsiveness. These metrics are critical as they influence the system’s ability to meet operational demands efficiently. For instance, a servo motor’s speed determines how quickly a machine can complete cycles, directly impacting production rates. Similarly, precision and torque affect the quality of output and the ability to perform under varying load conditions, respectively.

Influence of Servo Motor Condition on System Efficiency

Impact of Maintenance on Servo Motor Performance

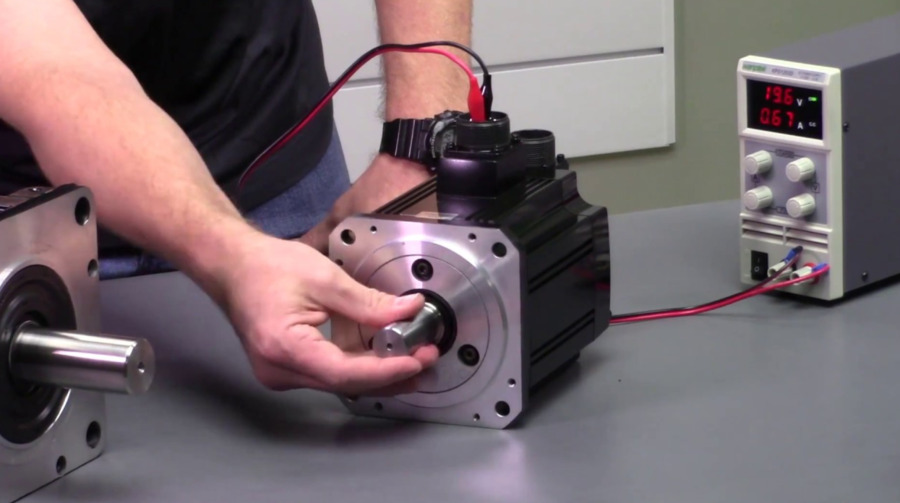

Regular maintenance is essential for sustaining the efficiency of servo motors. Effective maintenance regimes help preserve the motor’s ability to perform at optimal levels, directly influencing the machine’s overall productivity. For example, lubrication of moving parts prevents wear and tear, maintaining speed and accuracy. Similarly, checking and adjusting alignment ensures that the motor operates efficiently, reducing energy consumption and preventing premature wear. Proper servo motor repair and timely intervention are crucial in maintaining these standards.

Consequences of Neglected Servo Motor Maintenance

Ignoring the maintenance needs of servo motors can lead to a decline in their performance, which in turn affects the entire system. Poorly maintained motors may suffer from issues such as overheating, increased friction, or electrical failures, all of which can lead to machine downtime and costly repairs. Furthermore, a servo motor in suboptimal condition may use more energy to perform its tasks, leading to increased operational costs and reduced efficiency.

Benefits of Optimizing Servo Motor Efficiency

Enhanced System Output and Reliability

Maintaining servo motor efficiency is key to maximizing the reliability and output of the entire system. A well-maintained motor operates consistently at its intended capacity, supporting the system’s ability to meet production targets and maintain quality standards. This reliability is crucial for industries where downtime can result in significant financial losses and where consistent quality and output are necessary for maintaining market competitiveness.

Cost Efficiency and Longevity

The economic benefits of maintaining servo motors are significant. Effective maintenance extends the lifespan of these motors, reducing the frequency and severity of machine breakdowns and the associated repair costs. Moreover, efficient motors optimize energy use, lowering electricity costs. Investing in regular maintenance not only enhances performance but also reduces the total cost of ownership of the machinery.

Best Practices in Servo Motor Maintenance

Routine Inspection and Servicing

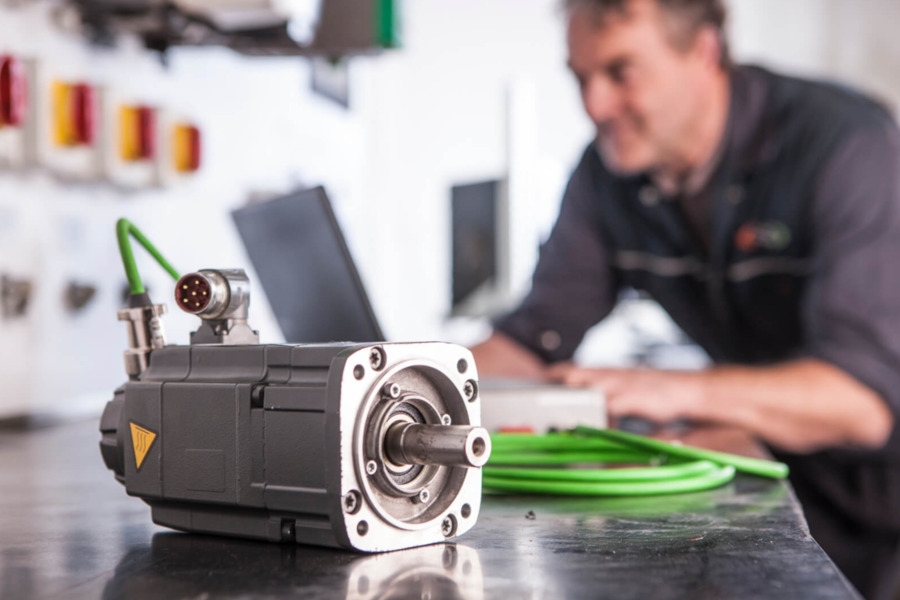

To ensure optimal performance, routine inspections and servicing of servo motors should be conducted. This includes tasks such as checking for signs of wear, verifying the integrity of electrical connections, and ensuring that all moving parts are well-lubricated. Modern diagnostic tools and sensors can be used to monitor motor conditions in real-time, alerting maintenance teams to potential issues before they lead to system failures.

Strategies for Efficiency Improvement

There are several strategies that can be implemented to improve the efficiency of servo motors. Retrofitting older motors with newer, more efficient models or components can significantly enhance their performance. Additionally, updating control software can provide more precise control over motor functions, improving speed and accuracy. Training maintenance personnel to recognize and address issues quickly and effectively is also crucial. As technology advances, continuing education in new techniques and innovations becomes essential.

Conclusion

The efficiency of servo motors is fundamentally linked to the performance of the machines they power. Maintaining these motors in excellent working condition enhances machine efficiency, reliability, and output while also providing significant cost savings through reduced downtime and operational expenses. As technology evolves, the importance of effective servo motor repair and maintenance by electro mechanical companies like Ghaima Group will only increase, underscoring the need for industries to adopt proactive and strategic maintenance practices. By focusing on regular maintenance and efficiency optimization, businesses can ensure that their machinery remains competitive and capable of meeting the demands of modern production environments.

Baseball fan, mother of 2, DJ, vintage furniture lover and creative consultant. Making at the intersection of art and programing to craft experiences both online and in real life. I’m a designer and this is my work.